Factory Tour - Reasearch and design |

|

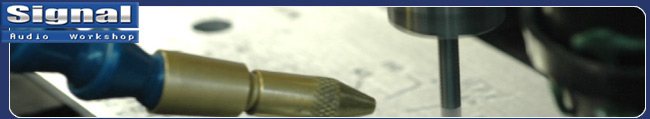

We use state of the art CAD-CAM processing station which enables

us to design the exterior body of our models before they go

into fabrication. |

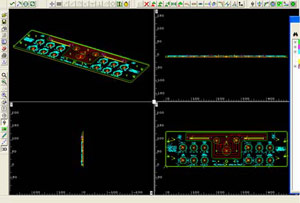

PCB drawing and track auto routing design station. |

This is our vintage AUMANN manual transformer winding machine

in which we hand wind audio transformers needed for our unique

designs. |

Our metal shop located in our compound |

CNC MACHINE IN ACTION: making unique parts essential for our

designs

|

| |

Factory Tour - Manufacturing |

Craftsman hand-touch hardware parts |

This is a combined metal 3-IN-1/760mm SHEAR PRESS BRAKE &

SLIP ROLL machine which we use on fabricating small metal

parts. |

Every vacuum tube used in our products goes through a series

of testes preformed in part, with our vintage Hickock model

539C Mutual Conductance Tube Tester, ensuring precision, performance,

spec quality and matching. |

PCB assembling is done meticulously by hand in our electronic

fabrication area. |

In final assembly stages, we test every product for spec performance

and run a series of quality assurance tests. |

Additional “burn in” tests and measurments are

done with all our vacuum tube products.

Additional “burn in” tests and measurments are

done with all our vacuum tube products. |

| |

|